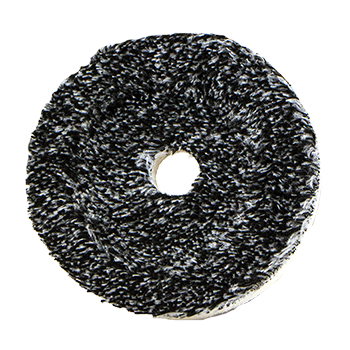

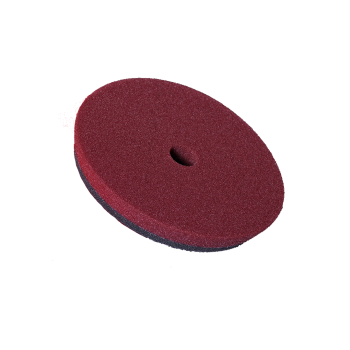

Buffing Pads

The vast variety of GLIPTONE wool and foam buffing pads can be overwhelming for anyone looking over these pages. Although there may be some redundancy, apart from user preference, the choice of pad usage will usually break down into the following four categories.

1. CUTTING/COMPOUNDING

2. SWIRL REMOVAL/POLISHING

3. FINISHING

4. ONE STEP PADS

NOTE: Remember to use the GLIPTONE ‘Body Clay Bar’, ‘Body Sponge’ or ‘Body Mitt’ to remove embedded surface contaminants prior to your initial buffing step! Regardless of whether or not the customer is paying for that process, it helps to make your buffing process much easier and far more effective! In the end, a standardized operating Detailing process that includes a ‘BODY BAR’, ‘Claying-Type’ process, will improve efficiency and long term profitability.